We often get asked ‘What is a self-level?”, “How does self levelling concrete work?”, “How much does self-levelling concrete cost?”. If any of these questions have crossed your mind then read this quick article on what self-levelling concrete is, how it works, and if it can work for you! DuraGuard Surfaces has been fortunate to work with self-levelling concrete in a variety of different capacities from small basement repairs, to entire hockey rink resurfacing! We are Grande Prairie and the Peace Country specialists in self-levelling products.

What Is Self Levelling Concrete?

Self Levelling Concrete – or self-levels – share many characteristics with typical concrete, however there are some key differences that allow it to function the way it does. Self Levelling concrete contains polymer-modified cement with high flow properties, without the need for additional water for placing as seen in typical concrete mixtures. Self-levels also don’t have any large aggregate in it, as they are designed to be installed at approximately 1/4″ (6mm) on average. Typically speaking self-level products are used to prepare a concrete floor for a floor coating such as tile, hardwoods, or vinyl however in the case of DuraGuard Surfaces we use self levelling concrete to remediate a semi-degraded concrete surface and apply an epoxy coating on top. In other scenarios self levelling concrete can be used as the wear surface, meaning it isn’t designed to be used as a self-leveling underlayment, whereas is a topping and is the finished surface.

Where Can Self Levelling Concrete Be Used?

Self Levelling Concrete can be used in a variety of areas with a multitude of applications. Self-levelling concrete is sometimes referred to as ‘liquid floor leveler’ is often used to remediate minor height differences in concrete from either improper placing and finishing or through the degradation and breaking down of the concrete itself. Sometimes pressure from below will heave the concrete slab creating a crack. Once the crack is repaired a self levelling concrete product can be placed on top of the existing concrete and relevel the space, making it usable, safe, and increasing the integrity of the floor. Some specific areas self-levelling concrete can be used are:

- Uneven or Heaved Basements

- Heaved or Sunken Garage Floors

- Heavily Spalled or Peeled Floors

- Exposed Aggregate Driveways & Walkways

- Heavily Degraded Shop Floors

Self Levelling Concrete can be used both indoors and outdoors, however not all self levelling products are designed to be used outdoors so it is prudent to research the products designed for your needs. Using self-leveling concrete outdoor comes with it’s own set of challenges as the product needs to be protected from weather during the curing process, not too dissimilar to regular concrete. A great example of an self-levelling concrete outdoor is Ardex K-301, we have used this product ourselves on several projects and absolutely love it!

There are also applications where self-levelling concrete can be used on wooden surfaces such as a bathroom or kitchen, however special precautions must be taken to properly prepare the floor to accept a self-level – otherwise you might have product running through your floor!

How is Self-Levelling Concrete Applied?

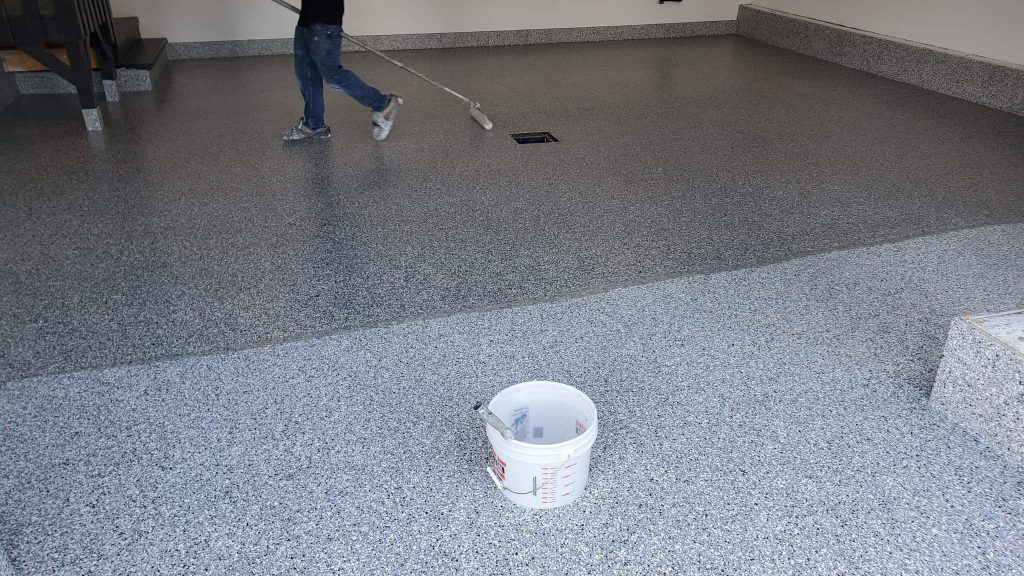

Most self-level products will come in a 40-50lb bag and are mixed onsite with a Collomixer or mixing drill and 5-gal pails or a garbage can. The mixture is then applied to the primed surface (either concrete or wood), and a gauge rake is used to move the product throughout the area in a consistent and smooth manner, without the product being applied too thin. Then a smoother is used to break the surface tension of the material and allow it to slowly flow and level itself over time. The chemical composition of the polymers in the product allow it to remain uniform and consistent throughout, creating an even and strong cure. Did you know that many self levels have a compressive strength equal-to, or higher than regular concrete?!

How Much Does Self-Levelling Concrete Cost?

In many cases, the product itself can range from $40-120/bag, with each bag covering approximately 23 sq ft @ 1/4″. Having an experienced contractor who has worked with self-levelling products can mitigate some of the problems with self-levelling concrete such as over- or under-applying, not priming correctly, or not installing on a suitable substrate which can all lead to shortened lifespans and premature degradation of the surface. Each floor presents it’s own unique set of challenges and characteristics, so each job needs to be taken independently of one another making a blanket square foot price incredibly difficult to predict. Having a reputable and experienced contractor install your self levelling concrete will definitely give you the best chance of success!